Battery Pressure Tester

Designed in U.S.

Our Products

-

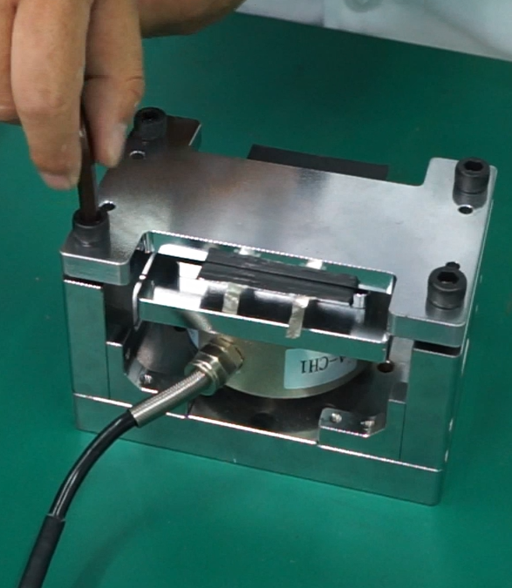

Electrodes

A device designed to measure swelling force of the electrodes.

-

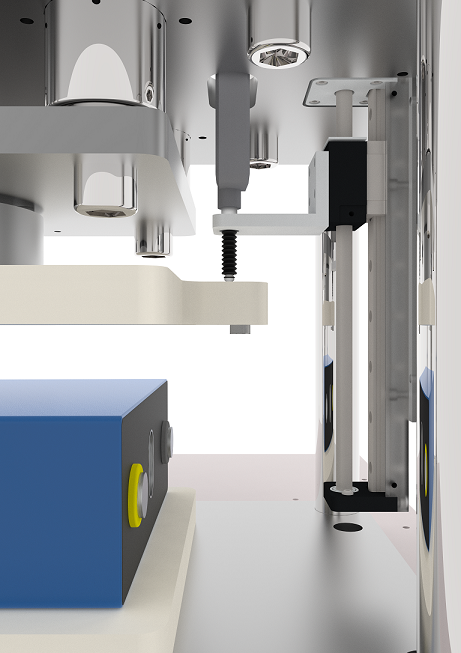

Pouch Cell

A device designed to measure swelling force of the pouch cell.

-

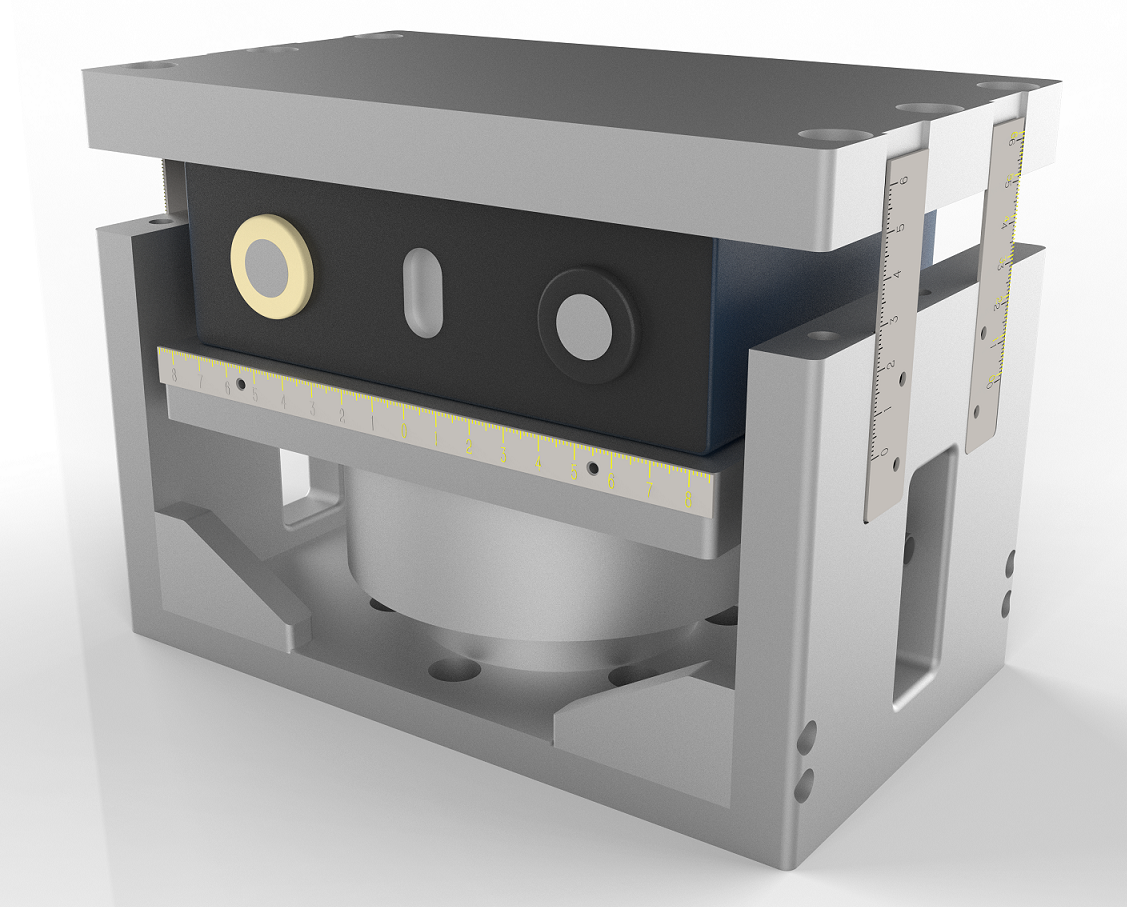

Prismatic Cell

A device designed to measure swelling force of the prismatic cell.

-

Blade Cell

A device designed to measure swelling force of the blade Battery.

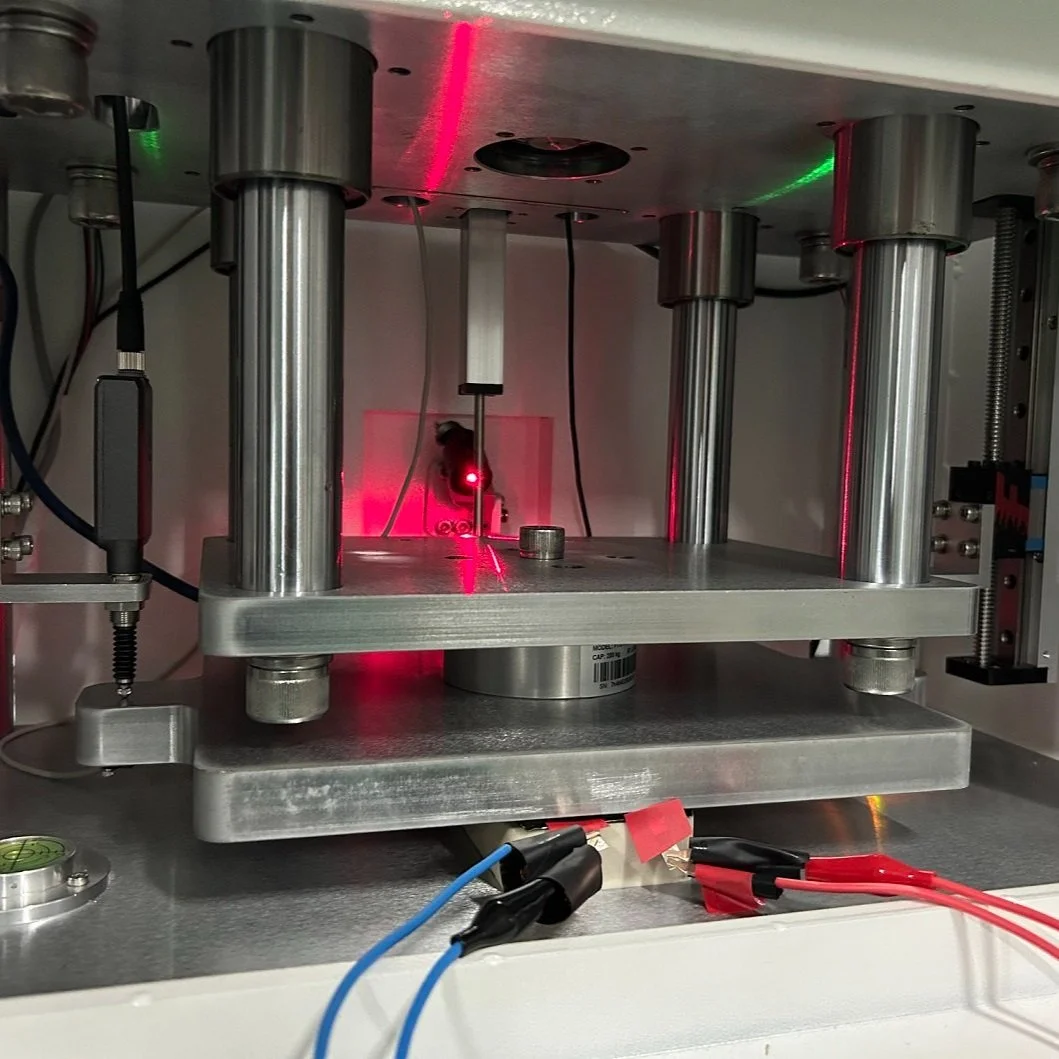

How it works?

This video introduces how to assemble the LIB swelling force test system with details. Please contact us if you meet any technical issue.

Our Cases

Our Story

As a minority-owned business in U.S., our team of passionate experts with backgrounds in electrochemistry, material science, solid mechanics, and mechanical engineering has been developing leading testing devices for energy storage system R&D.

We are at the forefront of battery technology, ensuring our testing facilities can accurately capture fundamental scientific data and solve real-world engineering challenges.

We have delivered more than 100 battery pressure testing devices to various end users, including battery manufacturers, OEMs, research institutions and universities.

Our Advantage

We know electrochemistry and we know mechanical engineering.

The accuracy deviation of the battery pressure measurement is no more than 0.5% in terms of the force measurement.

Fixture parallelism can be accurately set in the beginning and well maintained during the long-term cycling.

Our product can support up to 9 testing devices per controller, significantly simplifying the data transfer and lowering the cost.

Adaptable size and cable length to be sitting in other battery testing or characterization equipment, such as temperature chamber, ARC, DSC, etc.

Free software updates and technical support for our products.

Ready to Design Your Battery Tester?

InnCise team provides consulting service to customize the tester to fits your battery expansion test well. The design process usually takes 1 week and the manufacturing process usually takes 4 weeks.